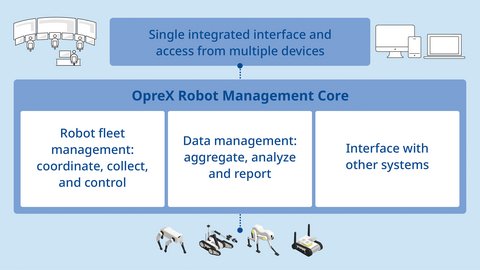

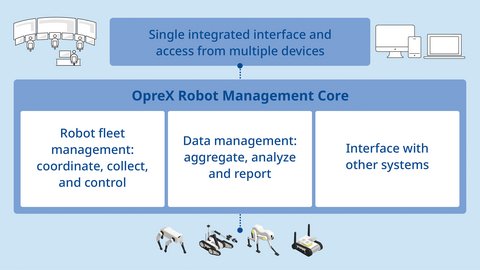

Yokogawa Electric Corporation has entered into a long-term strategic agreement with Shell Global Solutions International B.V. to co-develop and deploy advanced robotics and AI-driven solutions for industrial maintenance and monitoring. This partnership will see the integration of Shell’s proprietary machine vision system, known as Operator Round by Exception (ORE), into Yokogawa’s OpreX™ Robot Management Core platform.

The ORE system uses AI and machine vision to allow robots and drones to autonomously perform routine inspections—such as reading analog gauges, detecting fluid leaks, or identifying mechanical issues—tasks that traditionally require human operators. Developed over two years by Shell’s internal teams, ORE combines deep domain knowledge in equipment reliability with advanced visual recognition and analytics.

By embedding ORE into Yokogawa’s OpreX Robot Management Core, the software will significantly expand its capabilities, enabling automated inspections across energy, chemical, and heavy industrial plants. The platform allows seamless management of various types of robots and drones, integrating them with plant control and safety systems. The result is a major step toward more autonomous, efficient, and safe industrial operations.

Real-world Deployment and Innovation Roadmap

Yokogawa and Shell plan to pilot this integrated system at two Shell-operated facilities, testing how robotics and drone technology can streamline plant monitoring and reduce operator exposure to hazardous environments. The trials are expected to provide valuable insights into operational efficiency and cost savings.

This partnership also represents a major milestone at the Energy Transition Campus Amsterdam, where Shell fosters cross-sector collaboration to accelerate sustainable energy technologies. Both companies have committed to a shared R&D roadmap to continually enhance robotic inspection capabilities and visual intelligence technologies.

A Shared Vision for Safer, Smarter Plants

Masaharu Maeda, Vice President and Head of Yokogawa’s Solutions Business Division, commented:

“This partnership with Shell marks a new chapter in applying robotics and AI to address workforce safety and operational efficiency. We are excited to help industrial sites worldwide transition toward more intelligent and autonomous maintenance practices.”

Gerben de Jong, CIO at Shell for Integrated Gas, Upstream, and Projects & Technology, stated:

“Shell and Yokogawa share a strong history of collaboration in advanced automation. With this agreement, we’re building on that foundation to explore the full potential of AI and robotics in enhancing plant productivity and safety.”

About Yokogawa

Founded in Tokyo in 1915, Yokogawa provides cutting-edge measurement, control, and information solutions across energy, chemical, materials, and pharmaceutical industries. With over 17,000 employees and operations in 62 countries, the company continues to pioneer digital transformation and autonomous operations for a more sustainable future.

Learn more: www.yokogawa.com