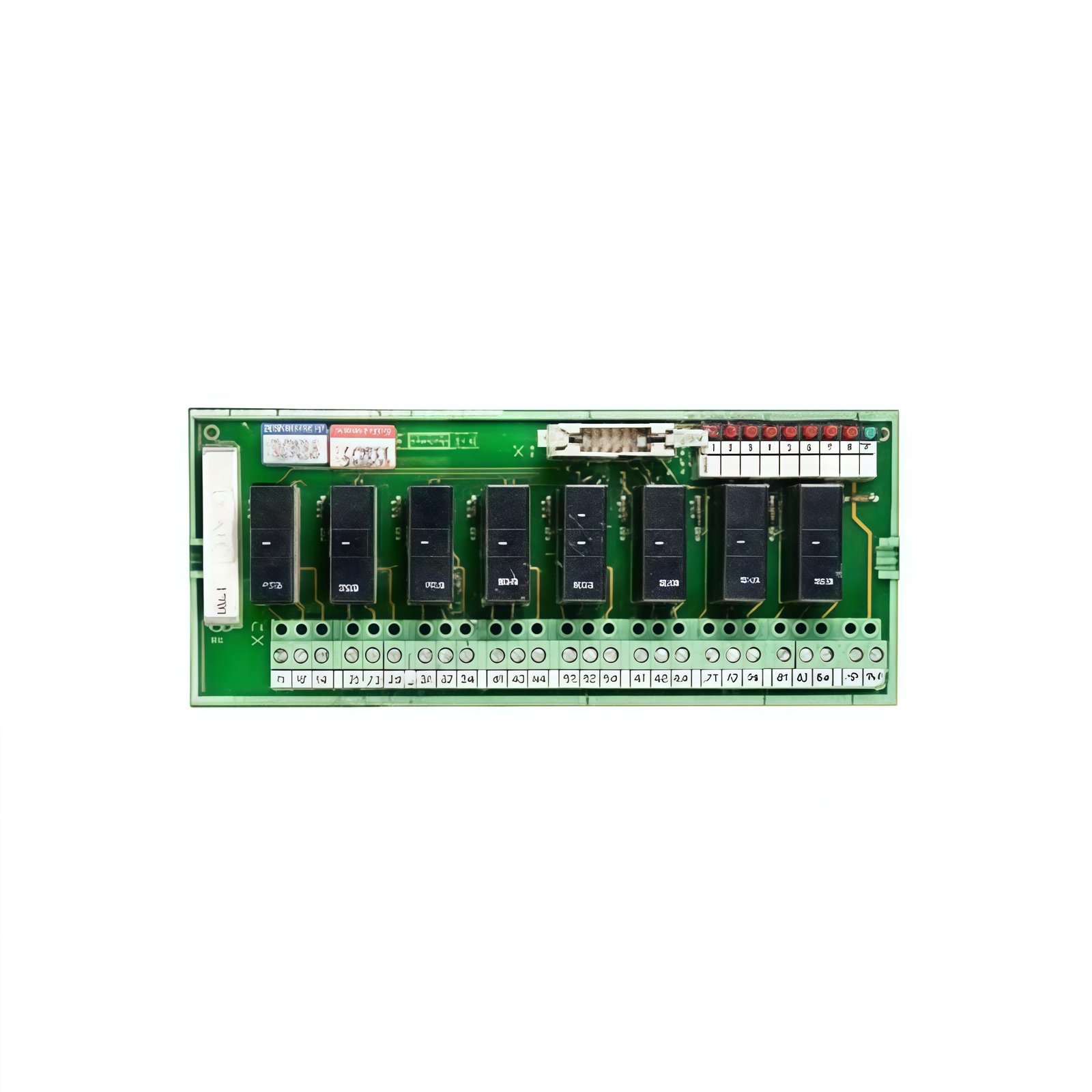

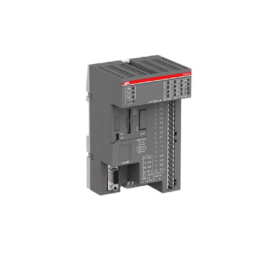

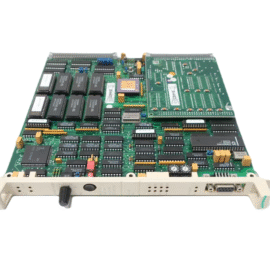

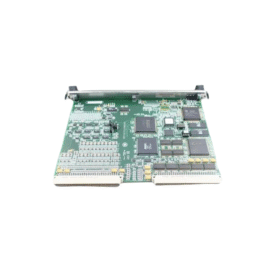

Product Overview

The Siemens PS02-3001V5.00 functions as a dedicated control module for industrial automation and process control applications. This module executes control logic, manages I/O communication, and coordinates system operations in manufacturing environments. We engineered the PS02-3001V5.00 to deliver reliable, high-performance control for demanding continuous processes and discrete manufacturing applications.

Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | Siemens |

| Model Number | PS02-3001V5.00 |

| Product Type | Control Module / Processor Unit |

| Processor Type | 32-bit RISC industrial microprocessor |

| Clock Speed | 400 MHz |

| Program Memory | 2 MB RAM (expandable), 4 MB Flash |

| Data Memory | 512 KB retentive, 8 MB load memory |

| Program Execution | 0.05 ms per 1K instructions |

| Digital I/O Capacity | 1024 points maximum |

| Analog I/O Capacity | 256 channels maximum |

| Communication Ports | 1 x PROFINET, 1 x PROFIBUS DP, 1 x RS-232 |

| PROFINET Interface | 2-port switch, 10/100 Mbps, RJ45 |

| PROFIBUS Interface | 9-pin D-sub, up to 12 Mbps |

| Real-Time Clock | Yes, battery-backed, accuracy ±2 seconds/day |

| Battery Backup | Lithium, 3V, 5-year typical life |

| Power Supply | 24 VDC ±20%, 500 mA typical |

| Power Consumption | 12 W maximum |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions (W x H x D) | 120 mm x 140 mm x 80 mm (approx.) |

| Weight | 0.8 kg (1.76 lbs) |

| Mounting | DIN rail (TS-35) or panel mount |

| Status Indicators | Run, stop, fault, force, maintenance, network status |

| Memory Card Slot | SIMATIC Micro Memory Card (MMC) |

| Certifications | CE, UL, cUL, CSA, ATEX (Zone 2), FM Class 1 Div 2 |

Key Features and Benefits

High-Speed Processing Performance: The PS02-3001V5.00 executes control programs rapidly with its 400 MHz RISC processor. You achieve fast logic solving and deterministic response times for time-critical applications like motion control and high-speed packaging.

Integrated Communication Interfaces: This module includes PROFINET and PROFIBUS ports directly on the unit. Consequently, you connect to distributed I/O, drives, and HMIs without requiring additional communication processors.

Large Program and Data Memory: With 4 MB Flash for programs and 8 MB load memory, you can implement complex control strategies. The 512 KB retentive memory preserves critical data through power cycles without battery support.

Flexible I/O Expansion: The PS02-3001V5.00 supports up to 1024 digital and 256 analog I/O points. You scale the system from small standalone machines to large distributed applications using the same controller.

Robust Industrial Design: Engineers designed this module for harsh environments with wide temperature tolerance and vibration resistance. The conformal-coated circuit boards resist humidity and corrosive atmospheres common in industrial settings.

Detailed Functional Description

The primary function of the Siemens PS02-3001V5.00 involves executing user-programmed logic to control industrial processes and machinery. Specifically, it reads input signals from field devices, processes this information according to the control program, and updates output signals to actuators. The module performs this scan cycle continuously, typically completing thousands of cycles per second. Furthermore, it handles communication with HMIs, SCADA systems, and other controllers, providing comprehensive visibility into the automation system.

Memory Architecture and Data Retention

We designed the PS02-3001V5.00 with a sophisticated memory system for reliable operation:

| Memory Type | Size | Purpose |

|---|---|---|

| Program Memory (RAM) | 2 MB | Executing control logic during runtime |

| Load Memory (Flash) | 8 MB | Storing user programs and configuration |

| Retentive Memory | 512 KB | Preserving critical data during power loss |

| Work Memory | 4 MB | Processing data and intermediate values |

| Removable Memory | Up to 32 GB (MMC) | Program backup, data logging, firmware updates |

Communication Capabilities

The PS02-3001V5.00 provides versatile connectivity for various automation networks:

PROFINET Interface: Integrated 2-port switch enables line topology without external switches. You connect up to 128 PROFINET devices for distributed I/O and drives.

PROFIBUS DP Interface: Connects to legacy PROFIBUS networks with up to 125 slaves. The module operates as a DP master, handling all cyclic and acyclic data exchange.

RS-232 Port: Supports point-to-point communication with printers, barcode scanners, and modems. You implement ASCII protocols for simple device integration.

Web Server: Built-in web server provides diagnostic pages and process data access. You monitor the system using standard web browsers without special software.

Programming and Configuration

Engineers program the Siemens PS02-3001V5.00 using the TIA Portal engineering framework. The module supports all five IEC 61131-3 programming languages:

Ladder Diagram (LD) for discrete logic

Function Block Diagram (FBD) for continuous processes

Structured Text (ST) for complex algorithms

Sequential Function Chart (SFC) for state-based control

Instruction List (IL) for optimized code

Configuration involves setting I/O addresses, network parameters, and communication relationships using intuitive graphical tools.

Mechanical and Installation Details

The Siemens PS02-3001V5.00 features a robust metal housing for industrial durability. Its DIN rail mounting clip allows quick installation on standard TS-35 rails without tools. The front panel provides easy access to communication ports, memory card slot, and status LEDs. Removable connectors for power and I/O simplify wiring and replacement. A protective cover over the memory card slot prevents accidental removal during operation.

Common Industrial Applications

The PS02-3001V5.00 serves as the primary controller for diverse automation applications:

| Application Area | Typical Use Case |

|---|---|

| Automotive Manufacturing | Controlling assembly line transfer systems |

| Food & Beverage | Managing batch processing and packaging lines |

| Pharmaceuticals | Executing validated recipes for drug production |

| Water Treatment | Coordinating filtration and chemical dosing processes |

| Material Handling | Controlling conveyor sortation and warehouse systems |

| Chemical Processing | Managing reactor sequences and safety interlocks |

| Packaging Machinery | Controlling high-speed filling and labeling equipment |

Why Choose This Module?

Selecting the Siemens PS02-3001V5.00 means choosing a powerful, scalable control solution for your automation needs. This module combines high-speed processing with integrated communication, reducing hardware costs and panel space. You implement complex control strategies with ample program memory while maintaining fast scan times for responsive machine control. The flexible I/O capacity allows system growth without controller replacement, protecting your initial investment. With support for multiple programming languages, you develop control logic using the approach best suited to each application. The PS02-3001V5.00 represents the ideal balance of performance, connectivity, and scalability for modern industrial automation systems.

Details

| Weight | 1.2 kg |

|---|---|

| Dimensions | 50 × 290 × 217 mm |

Reviews

There are no reviews yet.