Product Overview

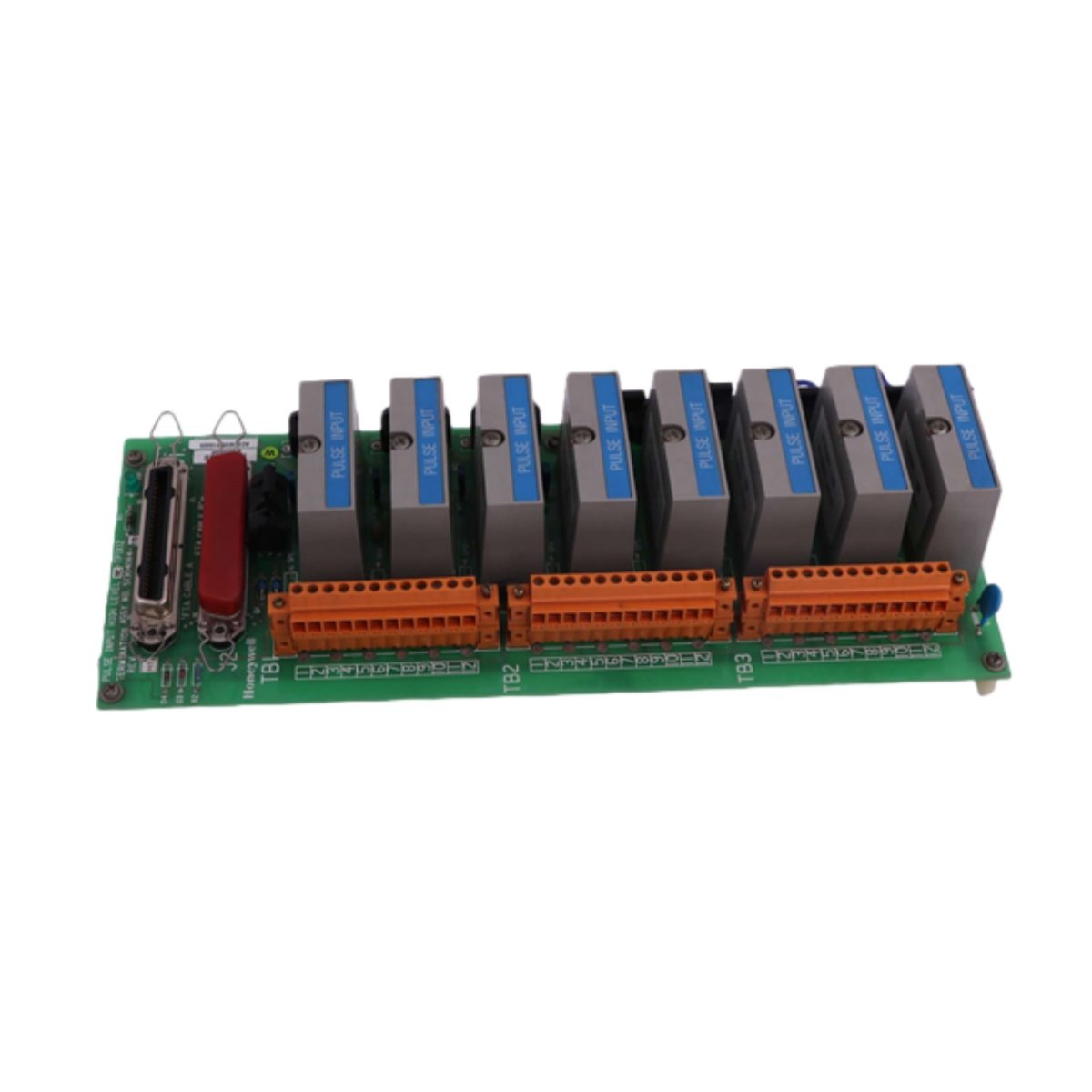

The Honeywell MC-TPIX12 functions as a specialized pulse input module designed for high-speed counting and frequency measurement applications. This module integrates seamlessly into Honeywell distributed control systems to capture signals from flow meters, encoders, and other pulse-generating devices. We engineered the MC-TPIX12 to deliver accurate totalization and rate monitoring for critical process variables in industrial environments.

Technical Specifications

| Parameter | Specification |

|---|---|

| Manufacturer | Honeywell |

| Model Number | MC-TPIX12 |

| Product Type | Pulse Input Module |

| Number of Channels | 12 independent pulse input channels |

| Input Signal Types | Dry contact, NAMUR proximity sensors, TTL levels |

| Maximum Frequency | 10 kHz per channel (typical) |

| Minimum Pulse Width | 50 microseconds |

| Input Impedance | 10 kΩ (typical) |

| Isolation Voltage | 1500 VDC channel-to-backplane isolation |

| Count Capacity | 32-bit counter per channel (up to 4.29 billion counts) |

| Power Consumption | 3.5 W maximum from backplane |

| Operating Temperature | 0°C to 60°C (32°F to 140°F) |

| Storage Temperature | -40°C to 85°C (-40°F to 185°F) |

| Dimensions (H x W x D) | 130mm x 25mm x 100mm (approx.) |

| Weight | 0.28 kg (approx.) |

| Termination | Removable screw terminal blocks |

| LED Indicators | Channel activity, module status, communication |

| Field Wiring | 14-26 AWG compatible |

Key Features and Capabilities

Multi-Channel High-Speed Counting: The MC-TPIX12 provides twelve independent channels for simultaneous pulse monitoring. Each channel supports frequencies up to 10 kHz, making it suitable for turbine flow meters and high-speed production counting.

Flexible Input Compatibility: You can connect various field devices directly to this module without additional signal conditioners. It accepts dry contacts, NAMUR proximity sensors, and TTL-level signals with equal ease.

Advanced Counter Functions: Each channel contains a 32-bit accumulator that stores total pulse counts with rollover handling. Furthermore, the module calculates frequency and rate values internally, reducing controller processing load.

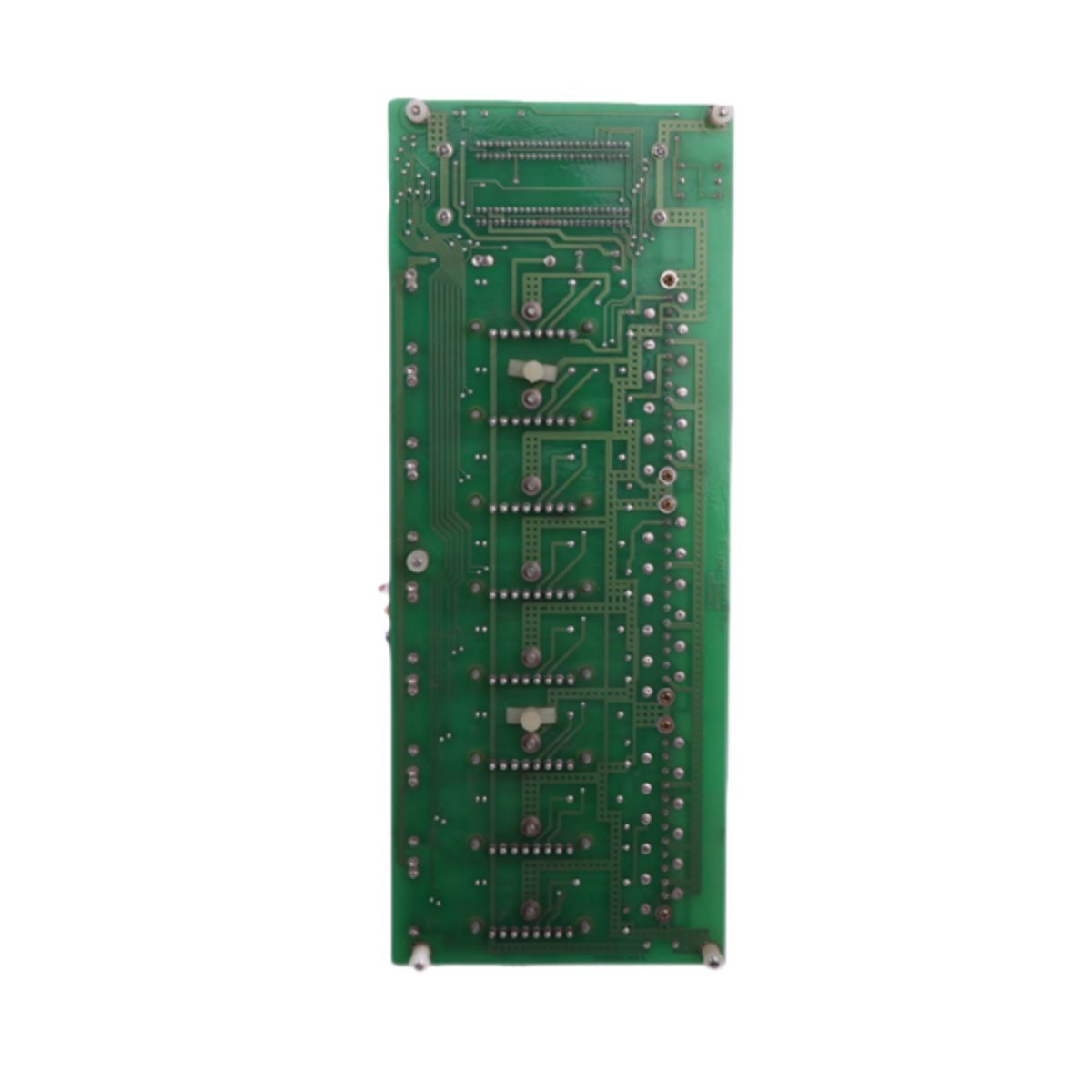

Industrial-Grade Isolation: The MC-TPIX12 features 1500 VDC isolation between field inputs and the system backplane. This protection prevents ground loops and shields sensitive control electronics from electrical transients.

Diagnostic Capabilities: Built-in diagnostic features monitor field wiring integrity and signal quality. Consequently, you can identify open circuits or sensor failures before they affect process measurements.

Detailed Functional Description

The primary role of the Honeywell MC-TPIX12 involves converting incoming pulse trains into meaningful process data. Specifically, it counts each pulse from flow meters or encoders and updates the accumulated total in real time. Additionally, the module measures the time between pulses to calculate instantaneous frequency or flow rate. The MC-TPIX12 then makes this data available to the controller through the backplane interface for use in control strategies, totalization, or reporting.

Input Characteristics and Signal Conditioning

We designed the input circuitry of the MC-TPIX12 to handle real-world industrial signals reliably. Each channel includes programmable threshold levels for different sensor types, ensuring accurate detection even with noisy signals. The module also provides 24 VDC loop power for NAMUR sensors, simplifying field wiring. For mechanical contacts, the built-in debounce filter eliminates false counts from contact bounce, ensuring accurate totalization.

Mechanical and Installation Details

The MC-TPIX12 features a compact, modular design that mounts directly into Honeywell I/O racks. Its front-accessible termination blocks allow you to connect field wiring without removing the module from the rack. Additionally, each channel includes a dedicated LED indicator that flashes with incoming pulses, providing immediate visual confirmation of field device operation.

Common Industrial Applications

You will find the MC-TPIX12 deployed across various industries where pulse counting and rate measurement are essential:

| Application Area | Typical Use Case |

|---|---|

| Oil & Gas | Custody transfer flow monitoring with turbine meters |

| Chemical Processing | Batch totalization for additive injection systems |

| Water Treatment | Flow measurement from positive displacement meters |

| Power Generation | Turbine speed monitoring with magnetic pickups |

| Food & Beverage | Production line counting and packaging control |

| Mining | Conveyor belt speed monitoring and material totalization |

Integration with Control Systems

The MC-TPIX12 operates as an integral component within Honeywell’s distributed control system architecture. It communicates with controllers such as the C300 through the standard I/O backplane, providing deterministic data exchange. Engineers can configure the module using standard engineering tools, setting parameters like input type, debounce time, and engineering units for rate calculations.

Why Choose This Module?

Selecting the Honeywell MC-TPIX12 means choosing a dedicated pulse input solution that offloads high-speed counting tasks from the main controller. Its twelve channels provide excellent density for multi-point monitoring applications, while the flexible input circuitry accommodates various sensor types without external hardware. With 32-bit counting resolution and 10 kHz frequency response, this module handles both slow totalization and high-speed events with equal precision. The robust isolation and diagnostic features ensure reliable operation in electrically noisy industrial environments, making the MC-TPIX12 a dependable choice for critical measurement applications.

Details

| Weight | 0.2 kg |

|---|---|

| Dimensions | 85 × 65 × 30 mm |

Reviews

There are no reviews yet.