Ensuring Personnel Safety and Equipment Protection

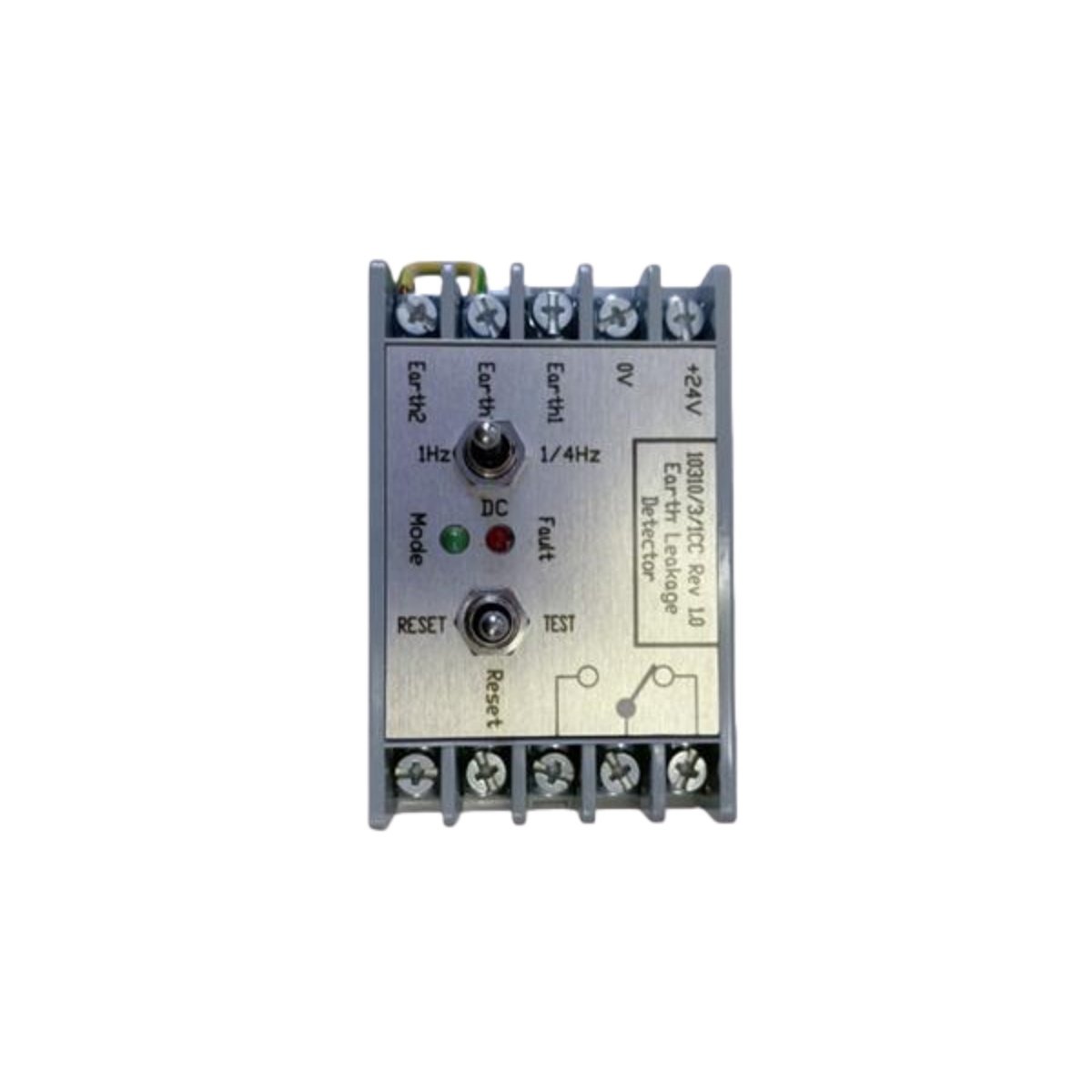

The Honeywell 10310/3/1CC is a dedicated earth leakage detector for critical safety systems. This module provides continuous monitoring of earth leakage current to prevent hazards. It is an integral component of the modular Honeywell Safety Manager System (SMS). Consequently, it helps protect both personnel from electrical shock and equipment from damage.

Technical Specifications and Functional Overview

This detector from Honeywell delivers accurate and reliable monitoring for industrial safety. Its design facilitates straightforward installation and maintenance within the SMS architecture. Furthermore, the module generates alarms based on configurable earth leakage current thresholds.

Detailed Technical Parameters

| Parameter | Specification |

|---|---|

| Manufacturer | Honeywell |

| Model Number | 10310/3/1CC |

| System Platform | Honeywell Safety Manager System (SMS) |

| Product Category | Earth Leakage Detector / Insulation Monitoring Module |

| Primary Function | Continuous Earth Leakage Current Monitoring & Alarm |

| Monitoring Principle | Current Transformer-based leakage detection |

| Number of Channels | 1 (Typical for single feeder monitoring) |

| Rated Current Sensing Range | 0 to 5 A (Typical for leakage CTs, verify with system docs) |

| Alarm Setpoints | Field-configurable via SMS engineering software |

| Response Time | < 100 ms (Typical for safety systems) |

| Output Signals | Discrete alarm relays & digital communication to SMS |

| Communication Interface | Integrated Safety Bus (to SMS controller) |

| Power Supply | 24 VDC (Supplied from SMS backplane) |

| Module Dimensions | Standard SMS module form factor |

| Module Weight | Approximately 0.3 kg |

| Operating Temperature | 0°C to 60°C (Standard for control room environments) |

| Mounting | Installs in a dedicated slot within the SMS chassis |

| Status Indication | LEDs for Power, Status, Alarm |

| Safety Integrity Level (SIL) | Suitable for use in SIL-rated safety loops (system dependent) |

| Certifications | Designed to meet relevant industrial safety standards |

Key Features and Safety Application

The 10310/3/1CC continuously monitors for insulation faults in electrical systems. It triggers immediate alarms upon detecting predefined dangerous leakage currents. This proactive detection helps prevent arc flash incidents and equipment ground faults. Moreover, its integration into the Safety Manager System allows for coordinated emergency shutdowns. This makes it a vital component for comprehensive electrical safety in hazardous areas.

Application Context and Industry Use

This detector is essential for safety-critical applications across several high-risk industries. It is commonly deployed in oil and gas production facilities and refinery electrical systems. The module also provides protection in power generation plants and chemical processing units. Furthermore, it finds use in pharmaceutical manufacturing and water treatment facilities. Therefore, the 10310/3/1CC serves wherever electrical safety is a paramount concern.

System Integration and Configuration

Installation involves placing the module into an available slot in the SMS rack. Technicians must connect the current transformer (CT) around the conductor to be monitored. Configuration of alarm thresholds and logic occurs within the Safety Manager engineering workstation. The module then communicates its status seamlessly to the central SMS controller for holistic safety management.

Details

| Weight | 0.68 kg |

|---|---|

| Dimensions | 145 × 100 × 40 mm |

Reviews

There are no reviews yet.