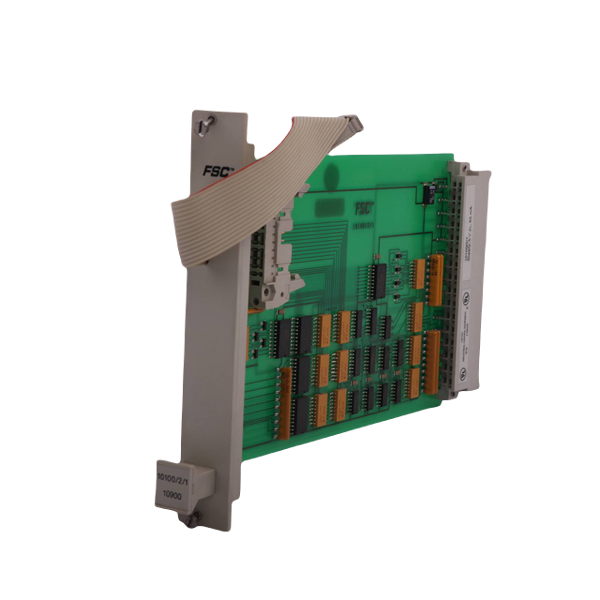

Product Overview

The Honeywell 10100/2/1 10900 Horizontal Bus Driver (HBD) is a critical communication interface for I/O rack systems. It connects horizontal and vertical bus flatcables, providing stable address selection and data transfer within both redundant and non-redundant configurations. Moreover, it plays a key role in ensuring synchronized communication between the I/O modules and the Central Part of the system.

The module integrates easily into existing Honeywell racks and supports hot swapping, allowing replacement without powering down the system—except in safety-related configurations, where shutdown is required.

Functional Highlights

- Dual Configuration Support: Works seamlessly in both redundant and non-redundant I/O setups.

- Flexible Cable Options: Compatible with A1, A21, and A22 flatcables for single or dual-rack redundancy.

- Hot-Swappable Design: Enables module replacement under power in standard systems.

- Reliable Communication: Maintains robust data exchange between vertical and horizontal buses.

- Compact and Efficient: Fits in a 4 TE × 3 HE space, ideal for dense control cabinets.

- Key Coding Safety: Includes mechanical coding to prevent incorrect rack insertion.

Technical Specifications

| Parameter | Description |

|---|---|

| Model / Type | 10100/2/1 10900 |

| Manufacturer | Honeywell |

| Approvals | CE, TÜV, UL |

| Software Compatibility | ≥ Version 3.00 |

| Physical Size | 4 TE × 3 HE (≈ 4 HP × 3U) |

| Power Requirements | 5 Vdc |

| Power Consumption | 35 mA (A1 / A21), 65 mA (A22) |

| Ripple Voltage | < 50 mV p-p |

| Connection Interfaces | CN1: Vertical bus; CN3: Horizontal bus |

| Module Keying | Holes A5, A7 |

| Rack Keying | Large pins A5, A7 |

Note: The HBD should be installed with appropriate flatcables (A1, A21, or A22) depending on the system’s redundancy level.

System Integration

The Honeywell 10100/2/1 HBD forms the communication backbone between the I/O modules and the system controller. It ensures stable signal routing across multiple racks in distributed control systems (DCS). Therefore, it is commonly used in process automation environments, including refineries, power generation, and chemical plants.

In addition, the module’s robust key coding and hot-swap capability minimize downtime and prevent incorrect installation during maintenance or expansion.

Details

| Weight | 0.5 kg |

|---|

Reviews

There are no reviews yet.