The GE DS3800NOAA1F1D serves as a specialized operational amplifier board within the Mark IV Speedtronic system, a series renowned for critical turbine management. This module handles precise signal conditioning tasks, ensuring accurate data flows between field sensors and the main controller. Engineers rely on this board to maintain signal integrity in harsh power generation environments. Consequently, the DS3800NOAA1F1D plays an integral role in stabilizing feedback loops for speed and temperature control.

Core Amplification Architecture

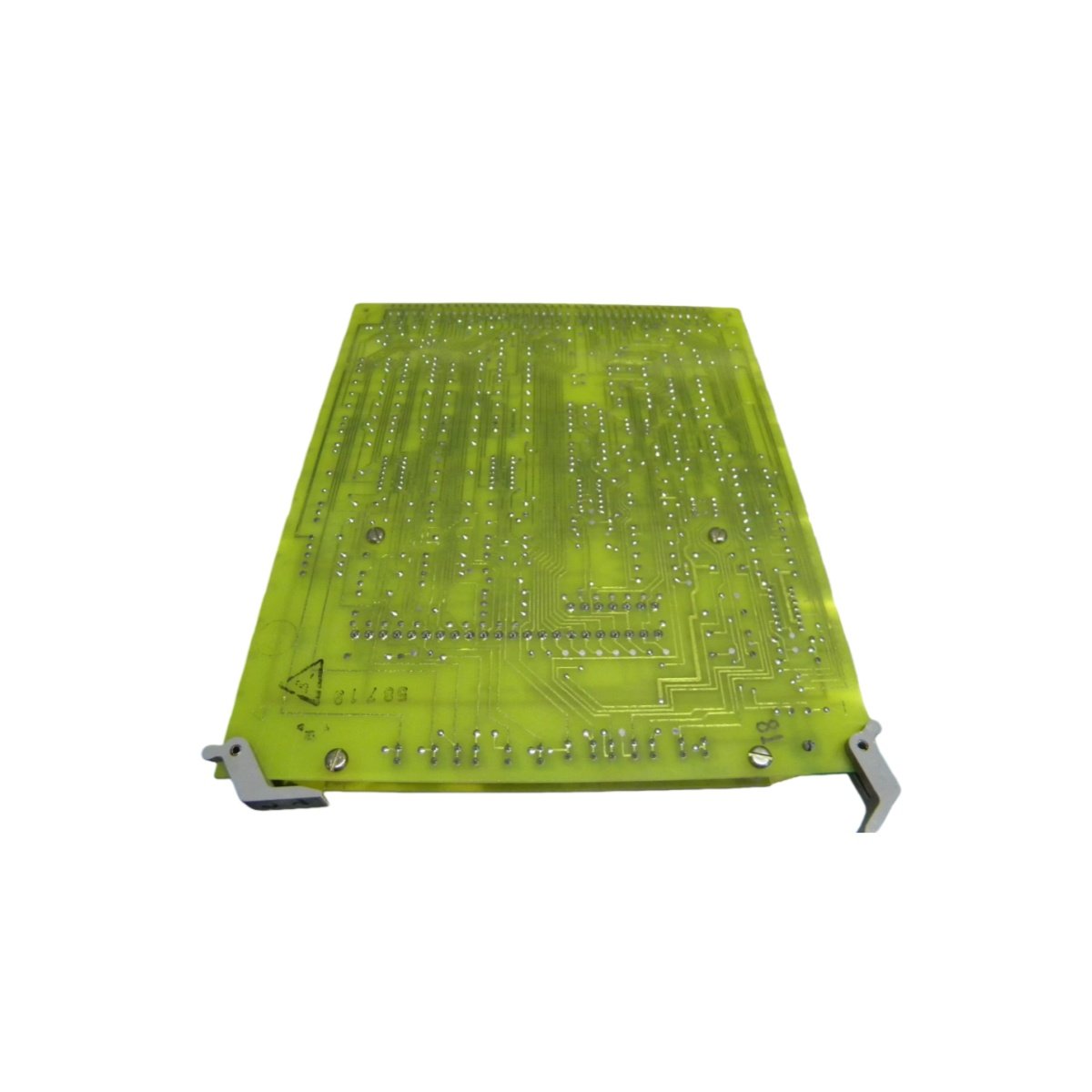

General Electric designed the DS3800NOAA1F1D with multiple high-grade operational amplifiers arranged for differential input processing. The board utilizes precision resistors and low-noise capacitors to minimize signal distortion during amplification. Each amplifier stage includes dedicated filtering components to reject electromagnetic interference from industrial settings. Additionally, the PCB features gold-plated edge connectors for reliable contact with the backplane. This robust design ensures consistent performance during critical turbine startup and shutdown sequences.

Technical Specifications and Physical Attributes

Understanding the exact specifications of the DS3800NOAA1F1D facilitates proper integration into existing Mark IV racks. The board’s compact form factor allows for high-density mounting within the control cabinet. Below you will find a detailed breakdown of its physical and electrical characteristics:

| Specification Category | Detailed Parameter |

|---|---|

| Product Type | Mark IV Operational Amplifier Board |

| Manufacturer | General Electric (GE) |

| Series | Speedtronic Mark IV |

| Dimensions | Approximately 12.0 inches (H) x 1.5 inches (D) x 9.0 inches (W) |

| Weight | Approximately 1.5 lbs (0.68 kg) |

| Board Material | High-temperature FR4 with multi-layer copper traces |

| Amplifier Stages | Four independent operational amplifier circuits |

| Passive Components | Over 120 precision resistors and ceramic capacitors |

| Energy Storage | Tantalum capacitors providing localized decoupling up to 220 µF |

| Input Interface | Two 60-pin edge connectors for backplane signal routing |

| Power Requirements | ±15V DC and +5V DC from rack power supply |

| Mounting Configuration | Vertical plug-in module within Mark IV chassis |

Functional Integration in the Mark IV System

Within the GE Mark IV architecture, the DS3800NOAA1F1D conditions analog signals from critical turbine sensors. It receives raw inputs from devices like speed pickups and thermocouples before sending clean signals to the processor. This board works in tandem with adjacent analog-to-digital converter cards for seamless data conversion. By maintaining precise gain control, it ensures the main controller receives accurate real-time data. Therefore, the DS3800NOAA1F1D directly supports the system’s ability to execute protective trip functions.

Reliability in Industrial Applications

The DS3800NOAA1F1D undergoes rigorous factory testing to meet GE’s standards for industrial durability. It suits various applications, including gas turbine control and steam turbine monitoring in utility plants. The board’s layout minimizes crosstalk between adjacent amplifier channels for superior signal purity. For facilities operating legacy Speedtronic systems, this module provides a reliable and direct replacement option. Its availability helps extend the operational life of critical turbine assets without requiring a full system upgrade.

Details

| Weight | 0.1 kg |

|---|---|

| Dimensions | 25 × 108 × 127 mm |

Reviews

There are no reviews yet.