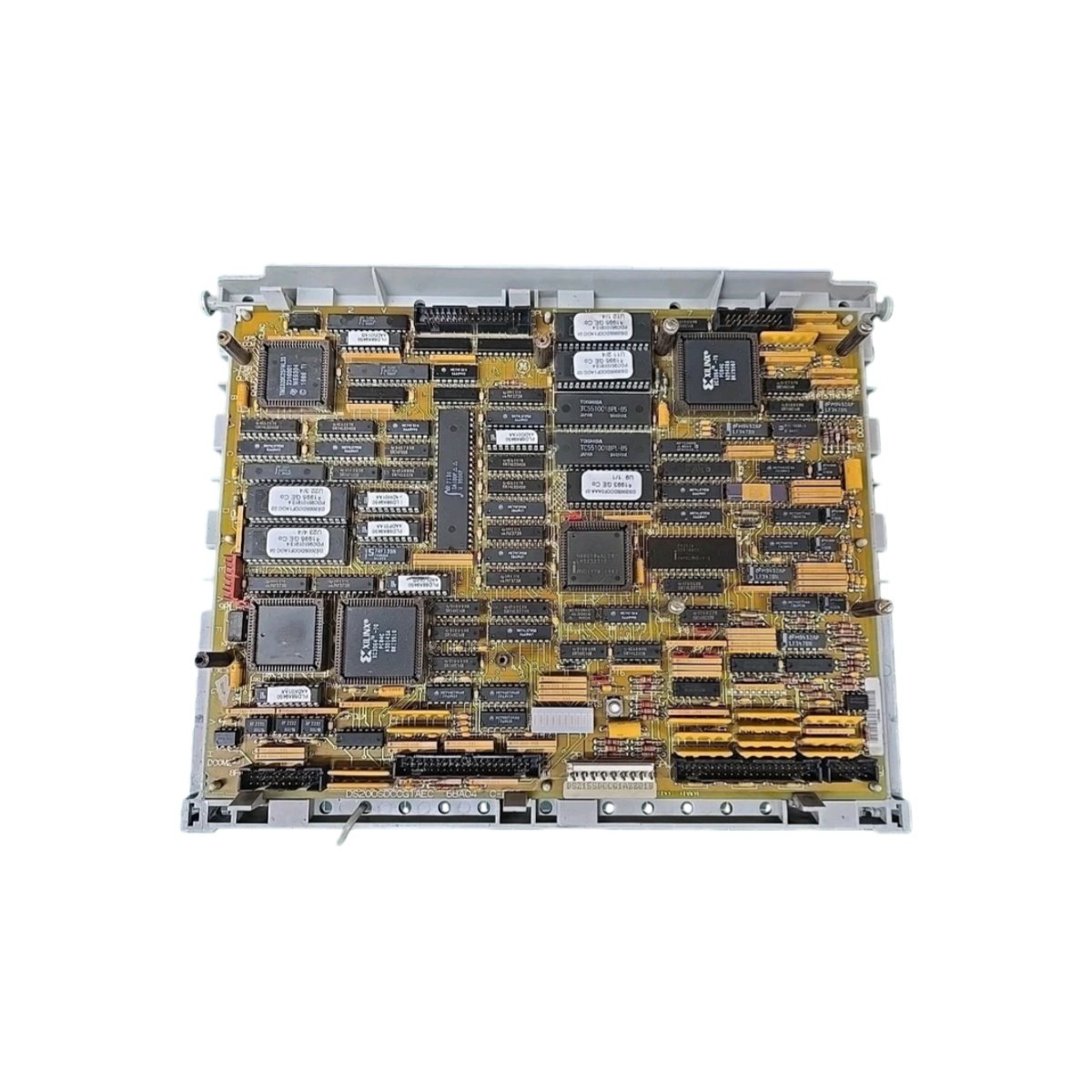

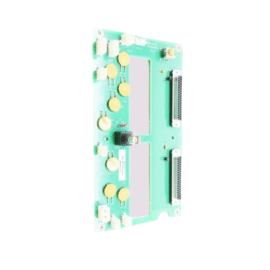

The GE DS200SDCCG1AGD DS215SDCCG1AZZ01B are high-performance drive control boards. They work together within the GE Speedtronic Mark V turbine control system. These specialized I/O modules deliver precise, reliable control for industrial drive systems.

Advanced Control for Critical Turbine Operations

These GE Fanuc boards facilitate exacting control over motors, gas, and steam turbines. They manage complex logic and high-speed signal processing for automation. Engineers designed these components for the demanding environments of power generation. Consequently, they ensure stable and efficient operation of critical rotating assets.

Detailed Technical Specifications

The following table provides the definitive technical parameters for these integrated control modules.

| Specification Category | Details for DS200SDCCG1AGD | Details for DS215SDCCG1AZZ01B |

|---|---|---|

| Manufacturer & Series | GE (General Electric) / GE Fanuc | GE (General Electric) / GE Fanuc |

| System Platform | Speedtronic Mark V Turbine Control System | Speedtronic Mark V Turbine Control System |

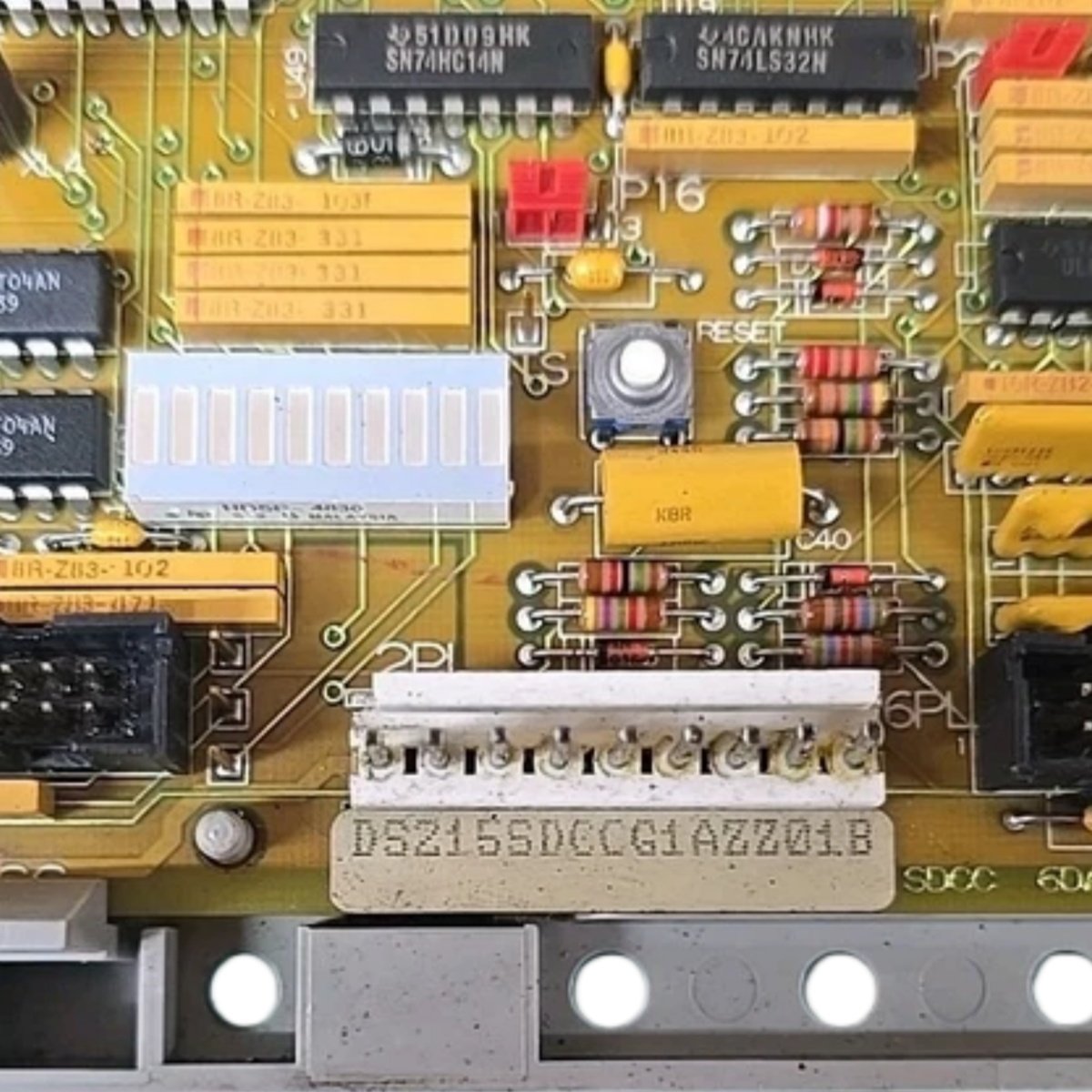

| Board Model | DS200SDCCG1AGD | DS215SDCCG1AZZ01B |

| Primary Function | Drive Control & Logic Processing Board | Complementary I/O & Control Board |

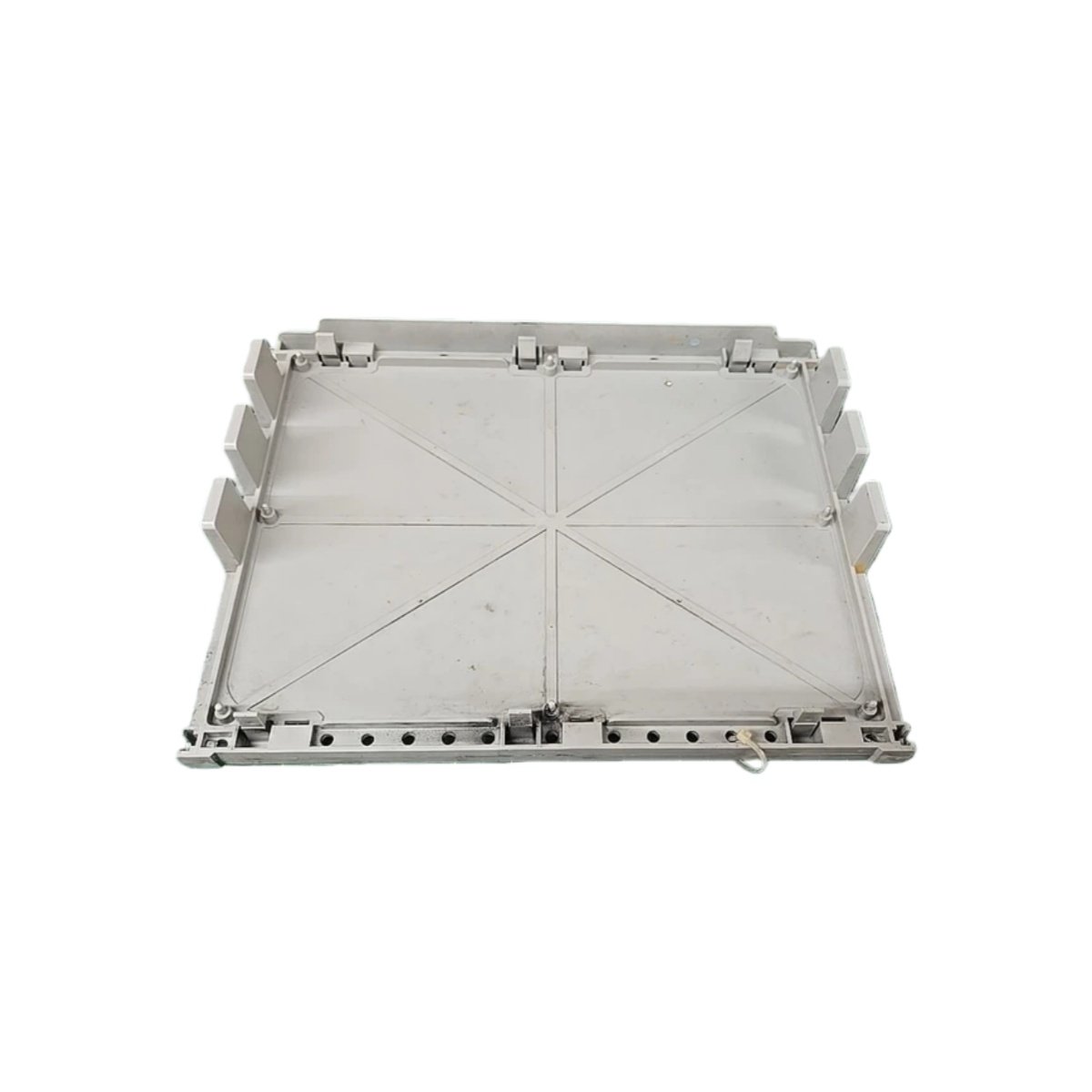

| Form Factor | Standard 6U board for Mark V rack chassis | Standard 6U board for Mark V rack chassis |

| Approximate Weight | ~0.5 kg (1.1 lbs) | ~0.48 kg (1.06 lbs) |

| Board Interface | High-density multi-pin connectors for backplane integration | High-density multi-pin connectors for backplane integration |

| Power Consumption | Derived from system backplane (typically +5VDC logic supply) | Derived from system backplane (typically +5VDC logic supply) |

| Key Components | Microprocessors, memory chips, communication controllers, and I/O drivers | Specialized ASICs, buffer chips, and signal conditioning circuits |

| Component Count | High-density SMT design with several hundred active/passive components | High-density SMT design with several hundred active/passive components |

Core System Functionality and Integration

The DS200SDCCG1AGD executes the primary control algorithms and logic sequences. Meanwhile, the DS215SDCCG1AZZ01B handles specific I/O expansion and signal interfacing tasks. They connect directly to the Mark V system’s high-speed data bus and backplane. This tight integration allows for real-time monitoring and adjustment of turbine parameters.

Application Value and Industry Role

Power plants and industrial facilities rely on these GE boards for automation and protection. They are critical for governing turbine speed, temperature, and pressure setpoints. Using these genuine, compatible modules ensures system reliability and data integrity. Ultimately, they form the dependable digital core for safe and efficient turbine operations.

Details

| Weight | 0.79 kg |

|---|---|

| Dimensions | 150 × 120 × 170 mm |

Reviews

There are no reviews yet.