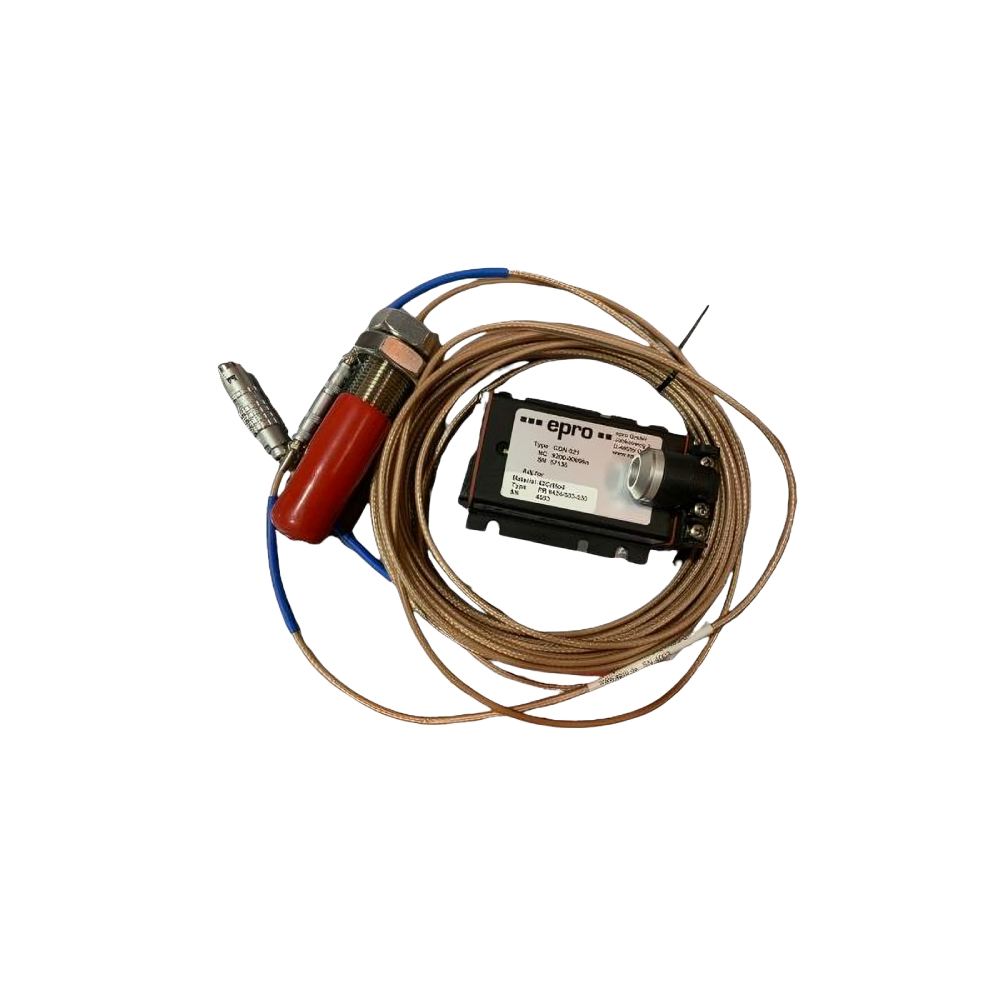

Product Overview

The Emerson PR6423-003-030-CN is a high-precision eddy current sensor for critical turbomachinery applications. Moreover, the CON021 signal converter processes sensor outputs for radial and axial shaft displacement, position, eccentricity, and speed. In addition, this combination provides robust and reliable measurement for turbines, compressors, pumps, and gearboxes. Its compact and rugged design supports installation in industrial environments with extreme vibration and temperature ranges.

Key Features & Functional Highlights

- Non-Contact Measurement: Accurately detects radial and axial shaft displacement without physical contact.

- High Precision Sensor: Linear measurement range of 2 mm, deviation ≤ ±0.025 mm.

- Signal Conversion: CON021 converts raw sensor data into standardized output signals with <1% linearity error.

- Environmental Tolerance: Sensor operates -35°C to +180°C, converter -30°C to +100°C.

- Robust Mechanical Design: IP66-rated sensor, stainless steel case, PTFE cable, and Lemo connector.

- High-Frequency Response: Signal converter frequency range 0–20 kHz with <15 µs rise time.

Technical Data

PR6423 Eddy Current Sensor

| Parameter | Specification |

|---|---|

| Linear Measurement Range | 2 mm (80 mils) |

| Initial Air Gap | 0.5 mm (20 mils) |

| Incremental Scale Factor | 8 V/mm ±5% @ 0–45°C |

| Minimum Shaft Diameter | 25 mm |

| Target Material | 42CrMo4 / AISI 4140 (others on request) |

| Protection Class | IP66 |

| Operating Temperature | -35°C to +180°C (sensor) |

| Cable Length | 8 m (1+7 m) |

| Connector | Lemo |

CON021 Signal Converter

| Parameter | Specification |

|---|---|

| Sensor Type | PR6423 |

| Measuring Range | 2.0 mm |

| Linearity Error | ≤1.0% |

| Operating Temperature | -30°C to +100°C |

| Shock & Vibration | 5 g @ 60 Hz @ 25°C |

| Protection Class | IP20 |

| Supply Voltage | -23V to -32V (Output: -4V to -20V) |

| Housing Material | LMgSi 0.5 F22 |

| Weight | ~120 g |

Typical Applications & System Integration

The PR6423 sensor and CON021 converter integrate into critical rotating machinery systems. Therefore, they are ideal for:

- Steam, gas, and hydro turbines for monitoring shaft displacement.

- Industrial compressors, pumps, and gearbox shafts requiring high-precision measurement.

- Speed and eccentricity monitoring for predictive maintenance programs.

- Integration with condition monitoring systems for real-time diagnostics.

Moreover, the combination provides consistent signal reliability in extreme industrial environments.

Details

| Weight | 0.58 kg |

|---|---|

| Dimensions | 610 × 584 × 102 mm |

Reviews

There are no reviews yet.