Product Overview

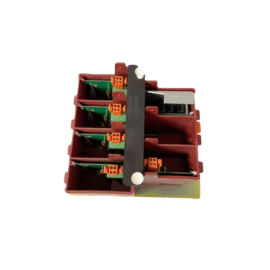

The Bently Nevada 330105-02-12-10-02-00 Reverse Mount Probe is a precision component from the 3300 XL 8 mm proximity transducer system. It provides accurate shaft vibration and position measurements in industrial rotating machinery. Designed for reverse mounting, it allows flexible installation in confined spaces without compromising accuracy or durability.

Moreover, the probe’s rugged design ensures consistent performance across extreme temperatures and mechanical stresses, making it ideal for continuous monitoring in turbines, compressors, and motors.

Functional Highlights

The 330105-02-12-10-02-00 offers excellent measurement stability and long service life, even under demanding operational conditions. Its PPS probe tip and stainless-steel housing ensure superior chemical and mechanical resistance.

Key Benefits:

- Reverse-mount design enables compact, flexible installation.

- Wide operating temperature range from -51°C to +177°C.

- Viton® O-ring seals differential pressure without pre-shipment testing.

- High-quality 75Ω triaxial FEP-insulated cable minimizes electrical interference.

- Compatible with Bently Nevada 3300 XL proximity transducer systems.

In addition, the probe features a Miniature ClickLoc connector for secure, vibration-resistant coupling, reducing signal loss and maintenance time.

Technical Specifications

| Parameter | Details |

|---|---|

| Model | 330105-02-12-10-02-00 |

| Series | 3300 XL 8 mm |

| Mounting Type | Reverse Mount |

| Operating & Storage Temp | -51°C to +177°C (-60°F to +350°F) |

| Probe Tip Material | Polyphenylene sulfide (PPS) |

| Case Material | AISI 303 / 304 Stainless Steel |

| Probe Cable | 75Ω triaxial, FEP-insulated |

| Cable Length | 1.0 m (3.3 ft) |

| Connector Type | Miniature ClickLoc coaxial, FluidLoc cable |

| Agency Approval | Not required |

| Pressure Sealing | Viton® O-ring |

Application Integration

This probe is optimized for integration into Bently Nevada 3300 XL monitoring systems, supporting reliable machine protection and condition monitoring. It measures dynamic shaft displacement and vibration in critical rotating equipment.

Common Applications Include:

- Steam and gas turbines

- Compressors and centrifugal pumps

- Electric motors and generators

- Gearboxes and drive trains

Therefore, the 330105-02-12-10-02-00 plays a crucial role in ensuring machine health and predictive maintenance.

Details

| Weight | 0.323 kg |

|---|

Reviews

There are no reviews yet.