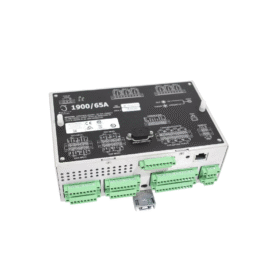

Product Overview

The Bently Nevada 3300/55 Dual Velocity Monitor delivers continuous and high-accuracy vibration monitoring for industrial rotating equipment. It integrates seamlessly into the 3300 Series Monitoring System, offering real-time data essential for predictive maintenance.

Moreover, it directly supports Velomitor®, HTVS, and Velocity Seismoprobe® transducers, eliminating the need for additional interface modules. Therefore, this model provides both simplicity and robust machine protection in demanding conditions.

Key Attributes:

- Dual velocity channels for independent monitoring

- Real-time vibration analysis and alarm functions

- Full compatibility with Bently Nevada 3300 systems

- API 670 compliant for standardized safety

Functional Highlights

This Dual Velocity Monitor enables flexible configuration through jumper-selectable sensitivity options—100, 145, or 500 mV/in/s. Each channel supports user-defined Alert and Danger setpoints, improving the precision of condition-based monitoring.

In addition, an integrated LCD display provides immediate visual feedback for both system health and vibration levels.

Benefits at a Glance:

- Customizable Filtering: High- and low-pass filter ranges (3–400 Hz and 24–3,000 Hz)

- Accurate Signal Conditioning: ±0.33% typical accuracy

- Energy-Efficient: Power consumption only 1.5 W

- Flexible Outputs: 4–20 mA, ±10 VDC, or 1–5 VDC recorder signals

- User Convenience: Buffered transducer outputs on both front and rear panels

Technical Data

| Parameter | Specification |

|---|---|

| Transducer Inputs | Velomitor®, HTVS, Velocity Seismoprobe® |

| Frequency Response | 3–10,000 Hz (Seismoprobe®), 3–3,000 Hz (Velomitor®/HTVS) |

| Filter Characteristics | 2-pole high- and low-pass, 40 dB/decade |

| Output Options | +4 to +20 mA, 0 to –10 VDC, +1 to +5 VDC |

| Power Consumption | 1.5 Watts |

| Display | 63-segment vertical bargraph per channel |

| Temperature Range (Operation) | 0°C to +65°C |

| Humidity | Up to 95% (non-condensing) |

| Compliance | API 670 |

| Alarm Relays | Epoxy-sealed, jumper-selectable |

| Model Number | 3300/55-01-04-12-12-00-00-05-00 |

Furthermore, its wide operational frequency range ensures precise detection of both low and high-frequency vibrations, which is crucial for protecting critical rotating assets.

System Integration & Application Scope

The Bently Nevada 3300/55-01-04-12-12-00-00-05-00 integrates smoothly with existing 3300 monitoring racks, providing scalable system protection. It is ideal for turbines, compressors, fans, and pumps that demand precise velocity and vibration analysis.

Additionally, its dual input design allows monitoring of two separate machine shafts or bearings simultaneously, reducing hardware costs while increasing diagnostic coverage.

Common Industrial Applications:

- Power generation and petrochemical plants

- Compressor and turbine monitoring systems

- Predictive maintenance programs

- OEM and retrofit vibration protection packages

Details

| Weight | 0.5 kg |

|---|

Reviews

There are no reviews yet.