System Overview

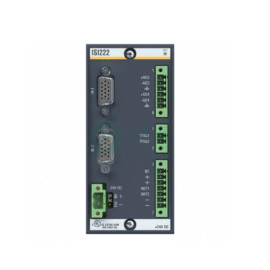

The Bently Nevada 3300/53-03-02-00-60-05-00-00-00 Overspeed Protection System provides real-time detection and shutdown protection against excessive turbine speed. It monitors shaft rotation through proximity probes and tachometer inputs, ensuring accurate overspeed detection under all conditions.

This 3-channel configuration is engineered for critical turbine applications, offering fast trip response, reliable relay control, and CE-certified safety compliance. Moreover, it integrates seamlessly with Bently Nevada 3300 rack systems for unified vibration and speed protection.

Core Functional Highlights

- Three Independent Channels: Provides triple-redundant overspeed detection for improved operational safety.

- Configurable Recorder Range: Supports up to 5000 RPM full-scale measurement accuracy.

- Flexible Power Input: Accepts 220 VAC supply for global industrial environments.

- High-Speed Event Detection: Up to 60 events per revolution, suitable for high-precision turbine monitoring.

- Comprehensive Alarms: User-programmable Alert and Danger alarms with four setpoints per channel.

- Industrial Durability: Operates reliably from 0°C to +65°C, ideal for demanding field conditions.

In addition, its short-circuit-protected outputs and LED diagnostics ensure consistent system operation and simplified troubleshooting during maintenance.

Technical Specifications

| Parameter | Specification |

|---|---|

| Model Number | 3300/53-03-02-00-60-05-00-00-00 |

| System Configuration | 3-Channel Overspeed System |

| Power Input | 220 VAC |

| Events Per Revolution | 60 |

| Recorder Range | 5000 RPM Full Scale |

| Input Signal | Two proximity probe transducer signals |

| Input Impedance | 10 kΩ |

| Scale Factor | 10 or 20 mV/mil (jumper selectable) |

| Accuracy | ±0.33% typical, ±1% max at +25°C |

| Recorder Output Options | +4 to +20 mA, 0 to -10 VDC, +1 to +5 VDC |

| Output Impedance | 100 Ω (min load 10 kΩ) |

| Alarm Range | Adjustable 0–100% of full scale |

| LCD Display | 63-segment bargraph per channel |

| Environmental Range | 0°C to +65°C operating, -40°C to +85°C storage |

| Humidity | Up to 95% non-condensing |

| Certifications | CE, CSA/NRTL/C, Class 1 Div 2, Groups A–D |

| Rack Space | 1 position (except 1 and 2) |

| Weight | 1 kg (2.2 lbs.) |

Therefore, the 3300/53 system not only provides protection against catastrophic turbine failures but also enhances overall reliability in high-speed rotating equipment monitoring.

Integration & Application Areas

The Bently Nevada 3300/53 Overspeed Protection System is specifically designed for turbomachinery, steam turbines, and gas turbines where overspeed conditions pose significant safety risks.

Common Integration Scenarios:

- Installed as part of a Turbine Supervisory Instrumentation system.

- Integrated with Bently Nevada 3300 or 3500 rack protection systems.

- Used for real-time speed measurement, trip logic control, and vibration correlation.

Furthermore, its modular rack compatibility enables users to expand protection capability without redesigning the system architecture.

Details

| Weight | 1 kg |

|---|

Reviews

There are no reviews yet.