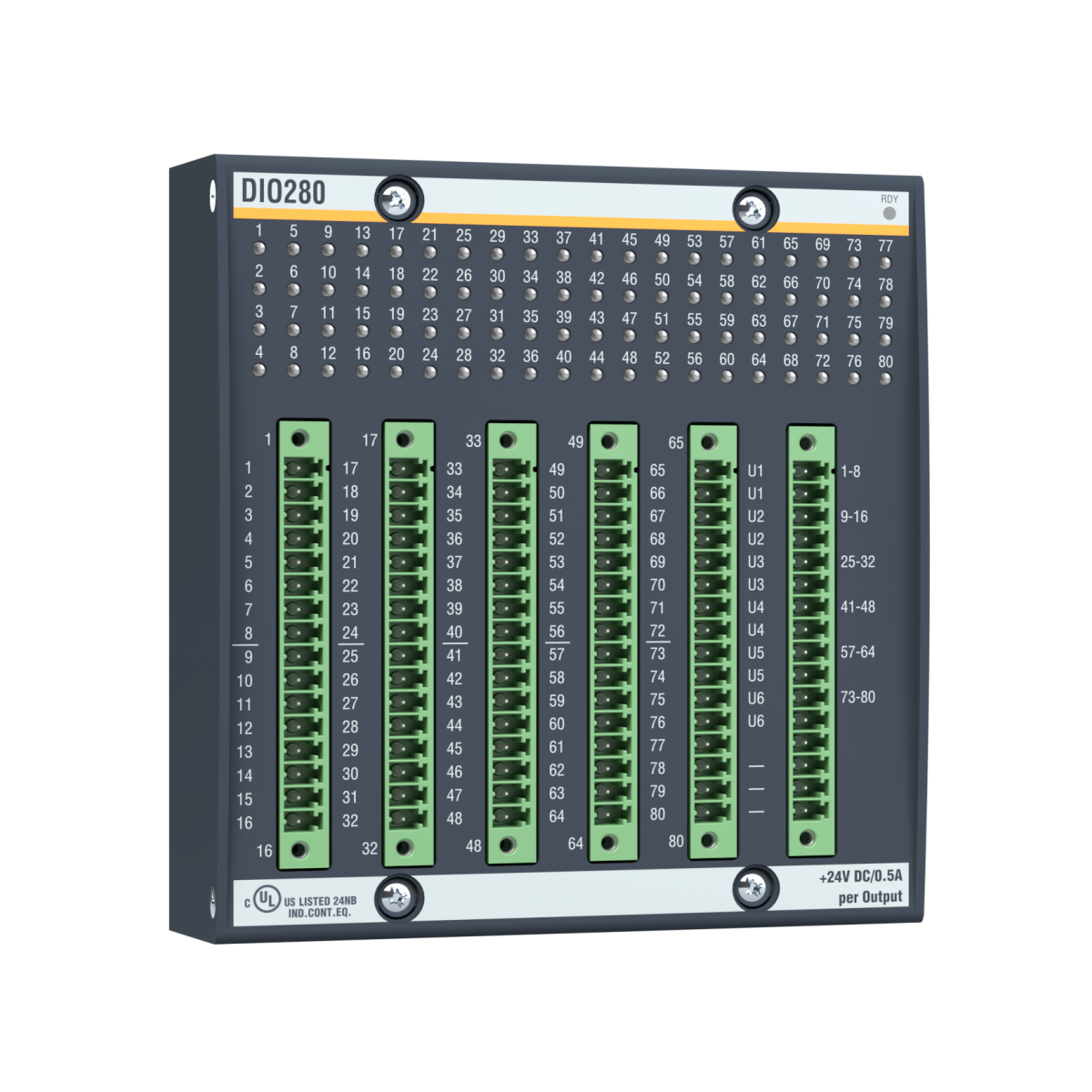

Versatile Digital Input/Output Modules for Automation Control

The Bachmann DIO248, DIO264, and DIO280 modules provide flexible digital input/output solutions for industrial automation. They control devices such as relays, contactors, and pneumatic or hydraulic valves. Moreover, they can read signals from sensors, detectors, and digital switches, making them ideal for PLC, DCS, and control system applications. Configurable interrupt inputs and counters allow rapid responses and precise monitoring in modern factory automation setups.

Key Features of Bachmann DIO Modules

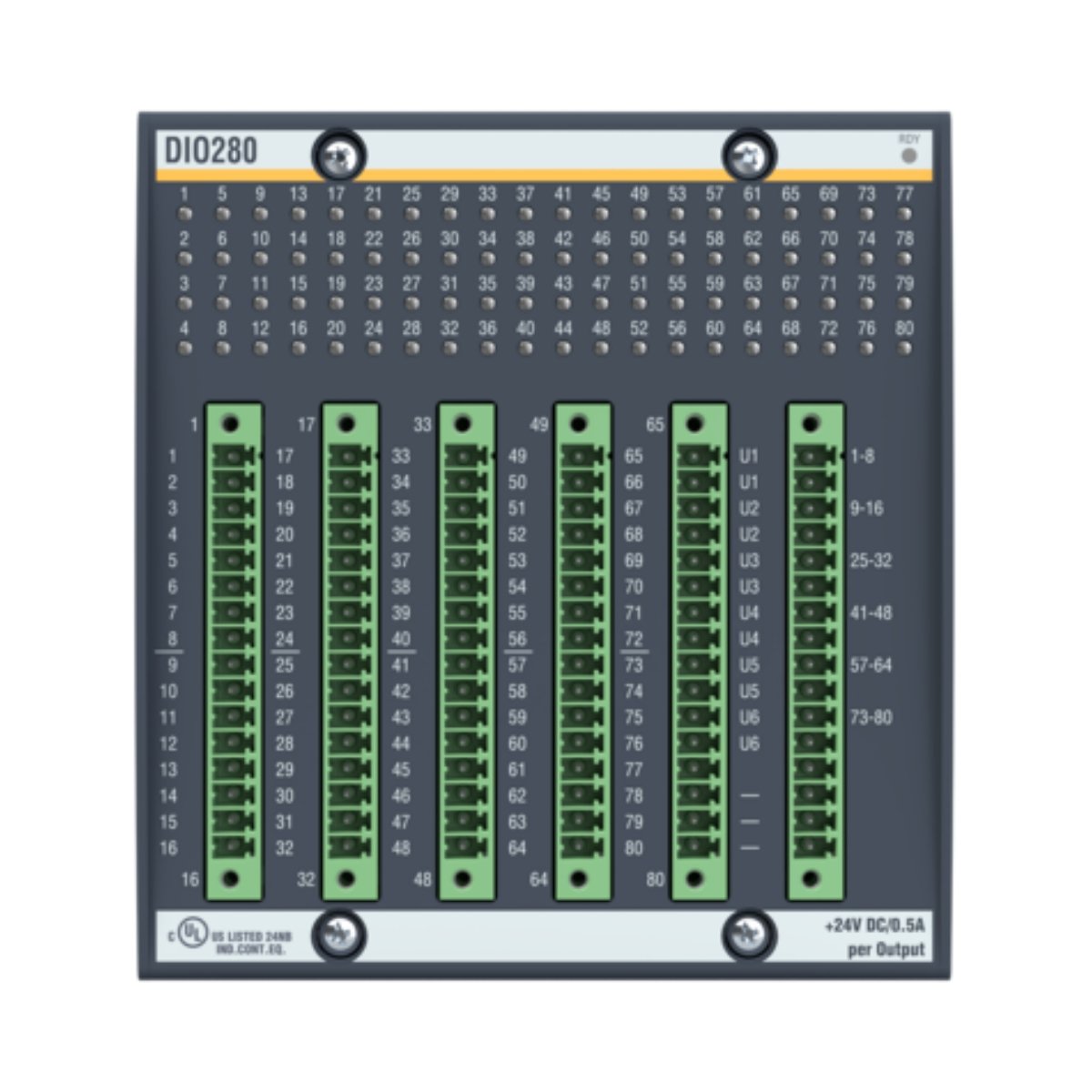

- Digital Channels: 48, 64, or 80 channels depending on model.

- Configurable Channels: Up to 16 channels can switch between input and output modes.

- Interrupt Inputs: 8 configurable inputs enable fast event handling.

- Counters: Four 32-bit counters for position detection, cycle counting, and material tracking.

- PWM Output Mode: Supports energy-efficient PWM operation with configurable hold times.

- Parallel Outputs: Outputs can connect in parallel for synchronized operation.

- Status Monitoring: Each channel has an LED for real-time status indication.

- Power Supply: Operates at 18–34 VDC with reverse polarity protection.

- Compact Design: Space-saving and cost-effective for industrial panels.

Technical Specifications

Inputs

- Quantity: 16–32 (DIO248), 24–40 (DIO264), 32–48 (DIO280)

- Voltage Range: High: 15–34 VDC, Low: 0–5 VDC

- Input Delay: Adjustable 10 µs–270 ms (standard 600 µs)

- Interrupt Inputs: 8, configurable as counters or interrupts

Counters

- Quantity: Up to 4, 32-bit resolution

- Operating Modes: Event, incremental encoder, gate measurement, cycle time, frequency

- Max Input Frequency: Single-channel: 50 kHz, Dual-channel: 20 kHz

Outputs

- Quantity: 16–48 depending on model

- Voltage: 18–34 VDC, Max current per channel: 0.5 A

- Total Current: 16–24 A

- Switching Frequency: 1 kHz for ohmic loads

- PWM: 13-bit resolution, 1 Hz–1 kHz frequency, hold time up to 2 s

Power Supply & Isolation

- 500 V galvanic isolation

- Reverse polarity protection and energy recovery from sensors

Environmental & Certifications

- Operating Temperature: -30°C to +60°C (-40°C to +60°C for cold climate)

- Humidity: 5–95% (operation), up to 95% with condensation (storage)

- Certifications: CE, cULus, CCC, DNV GL, LR, ABS, BV

- Dimensions: 110 x 119 x 61 mm; Weight: 385 g

Applications in Industrial Automation

- Industrial control systems and factory automation

- Machine and process control, robotics

- Data acquisition and monitoring systems

- Transportation, aerospace, and defense sectors

- Integration with PLC, DCS, and advanced control systems

Author’s Insight

The Bachmann DIO280 module stands out for its combination of flexibility, high-speed interrupt handling, and energy-efficient PWM outputs. In my experience, modules with configurable channels and counters significantly reduce wiring complexity in large-scale industrial automation projects. Moreover, the module’s compact footprint and robust environmental ratings make it suitable for harsh production environments and marine applications. Implementing such I/O modules can improve operational reliability, reduce downtime, and streamline maintenance.

Solution Use Cases

- Automated Manufacturing Line: DIO280 modules manage relays and pneumatic actuators, integrating seamlessly with PLC-based systems.

- Robotics: High-speed counters track motion accurately for pick-and-place operations.

- Process Control Systems: Interrupt inputs allow rapid detection of system faults, ensuring continuous operation.

- Transportation Systems: Modules handle signal acquisition and control for smart railway and vehicle automation.

- Aerospace & Defense: Reliable digital I/O ensures mission-critical control in demanding environments.

Details

| Weight | 0.385 kg |

|---|---|

| Dimensions | 110 × 119 × 61 mm |

Reviews

There are no reviews yet.