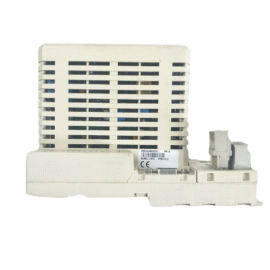

Product Description

The Allen-Bradley 1440-TPS02-01RB XM-320 is a high-performance position and process measurement module designed for turbine supervisory applications. It measures axial position, valve position, case expansion, and differential expansion with exceptional accuracy. Moreover, its built-in self-test ensures reliable operation at startup, helping technicians identify issues before system commissioning. The MS indicator displays clear diagnostic states, making troubleshooting straightforward and fast.

Functional Highlights

This module combines robust signal processing with reliable communication interfaces for industrial monitoring.

- Dual Measurement Channels: Supports eddy current and LVDT transducer inputs for flexible sensor integration.

- Configurable Power Supply: Provides isolated ±24V transducer power for stable signal measurement.

- Comprehensive Diagnostics: Includes self-test, LED indicators, and external reset switch.

- Flexible Communication: Works with DeviceNet protocol and RS-232 configuration for easy network integration.

- Rugged Design: Operates in temperatures from –20°C to +65°C, suitable for harsh industrial sites.

In addition, its nonvolatile memory preserves configuration settings, reducing downtime after power cycles.

Technical Specifications

| Parameter | Details |

|---|---|

| Brand | Allen-Bradley (Rockwell Automation) |

| Model / Catalog No. | 1440-TPS02-01RB |

| Measurement Inputs | 2 channels for eddy current or LVDT signals |

| Transducer Power | Isolated ±24V |

| Output Signals | 2 × 4–20mA isolated outputs, 600 Ω load |

| Communication Interfaces | DeviceNet, RS-232 |

| Relay Output | 1 DPDT, 125V AC/DC, 3.5 A max |

| Alarm Configuration | 2 alarm/danger pairs with hysteresis and startup inhibit |

| Power Supply | 24V DC, max 200 mA (5.28 W) |

| Operating Temperature | –20 to +65°C |

| Vibration / Shock | 2 g @ 10–500 Hz / 15 g operating |

| Certifications | CE, UL, ATEX, C-Tick |

| Dimensions | 97 × 94 × 94 mm |

Furthermore, the 1440-TPS02-01RB supports head-to-head and radial cancel modes, ensuring accuracy in complex turbine dynamics.

System Integration

The XM-320 position module integrates seamlessly with other XM Series monitoring components and the DeviceNet network. It enables centralized turbine data collection, improving predictive maintenance strategies. Therefore, it is widely used in power plants, petrochemical refineries, and industrial turbine systems. For instance, it monitors critical shaft or valve movements to prevent mechanical stress and unplanned shutdowns.

Details

| Weight | 0.268 kg |

|---|---|

| Dimensions | 2464 × 2388 × 2388 mm |

Reviews

There are no reviews yet.